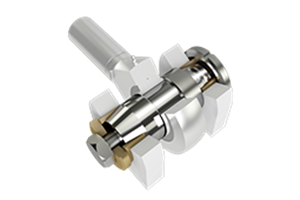

EXPANDER® – A refined and cost-effective solution to the wear of pivot shafts.

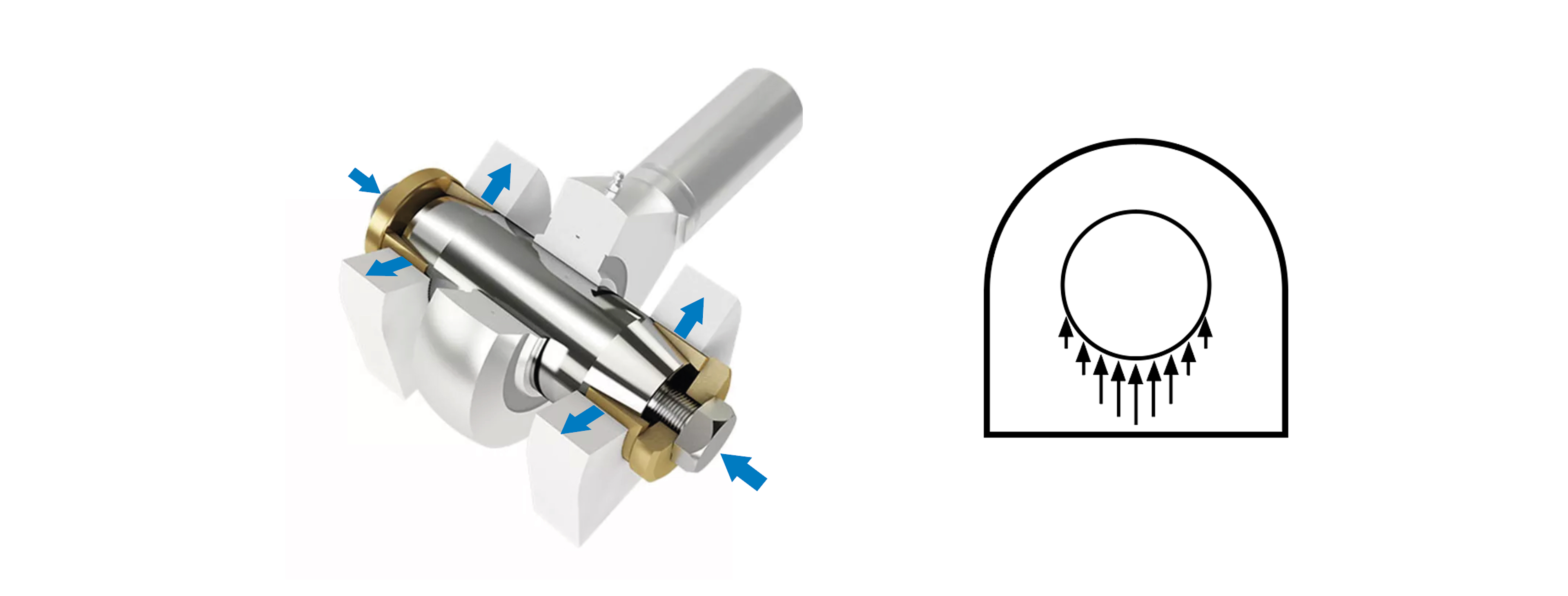

Expander® is a patented technology for pivot shafts designed to provide a permanent solution to the wear of pivot bearings, without the need for welding or machining to re-bore the bearing sleeves.

Thanks to this innovative principle, the shaft securely attaches even to worn bearings, eliminating play and significantly extending the lifespan of the equipment.

Expander® Product Range

Nuts and Washers

Applications Without Obstacles Around the Pivot Shaft

Fastening Bolt with Washer

Applications Without Obstacles and Pivot Shaft Diameters Greater Than 38 mm

Fastening Bolt with Embedded Washer

Applications with Moving Obstacles and Wide Ears

Through Bolt Design

Applications with Space Constraints on One Side

Flat Head Fasteners

Applications with Moving Obstacles and Narrow Ears

Multi-Bolt Solutions

High-Performance Applications with Large Diameters

Shoulder Shaft

Shoulder Shaft with Axial Locking for Coupling Pin Applications

Offshore Shaft

Offshore Applications: DNV 2.22/OS E-101 and AP 8C/ISO 13535 Standards

The Perfect Shaft for Any Application

No matter your application—large, small, high volume, or a single piece—Expander is the solution you need.

With experience in designing systems for over 80,000 applications, Expander products will address all your shaft-related challenges. All systems can be supplied in any diameter and length, with internal or external lubrication options and material certification.

The design of the products can be customized to meet application needs, such as space constraints, single-side mounting, or embedded installation.

Expansion sleeves expand and lock the system in place, permanently eliminating wear on the joints.

The Expander system is installed directly into the existing support, eliminating play and distributing the load effectively.

The Strength of Your Machine is Defined by Its Shafts

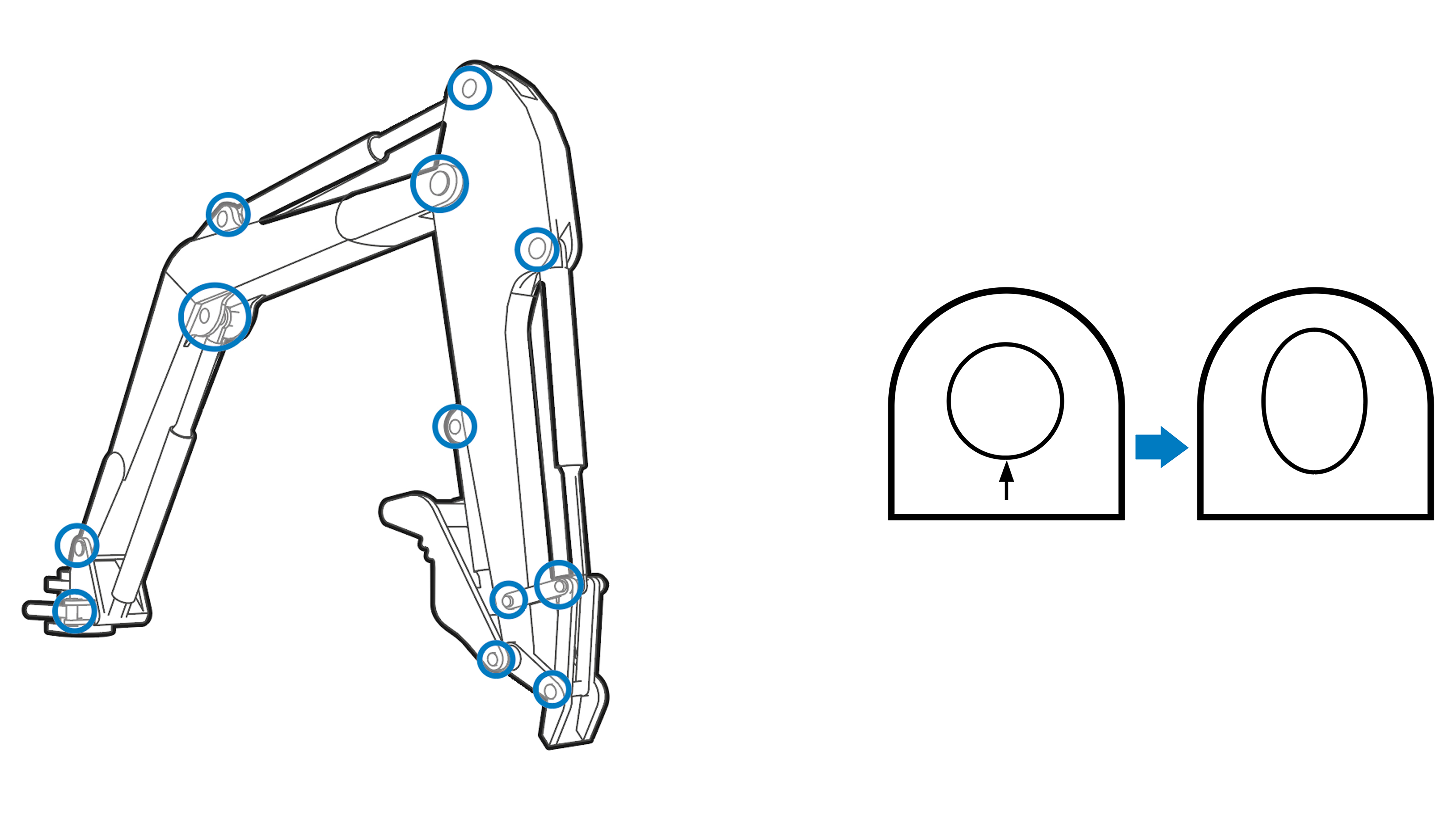

Wear on joints is a common issue in all machines.

Bearing wear occurs due to the play between the bore and the conventional shaft.

The performance of joints directly affects a machine's ability to perform its task safely and with high precision.

When a machine operates, the load is concentrated on the bearing surfaces. Wear occurs on these surfaces because they are made from the most fragile material.

Wear on the bearing surfaces leads to increased vibrations and a decrease in precision and stability.

Wear on the bearing surfaces is typically repaired by re-boring, a lengthy and costly procedure.

This traditional repair method addresses joint wear but does not prevent it from recurring.

With the Expander system, repairs can be made directly on worn mounts without the need for welding or re-boring.

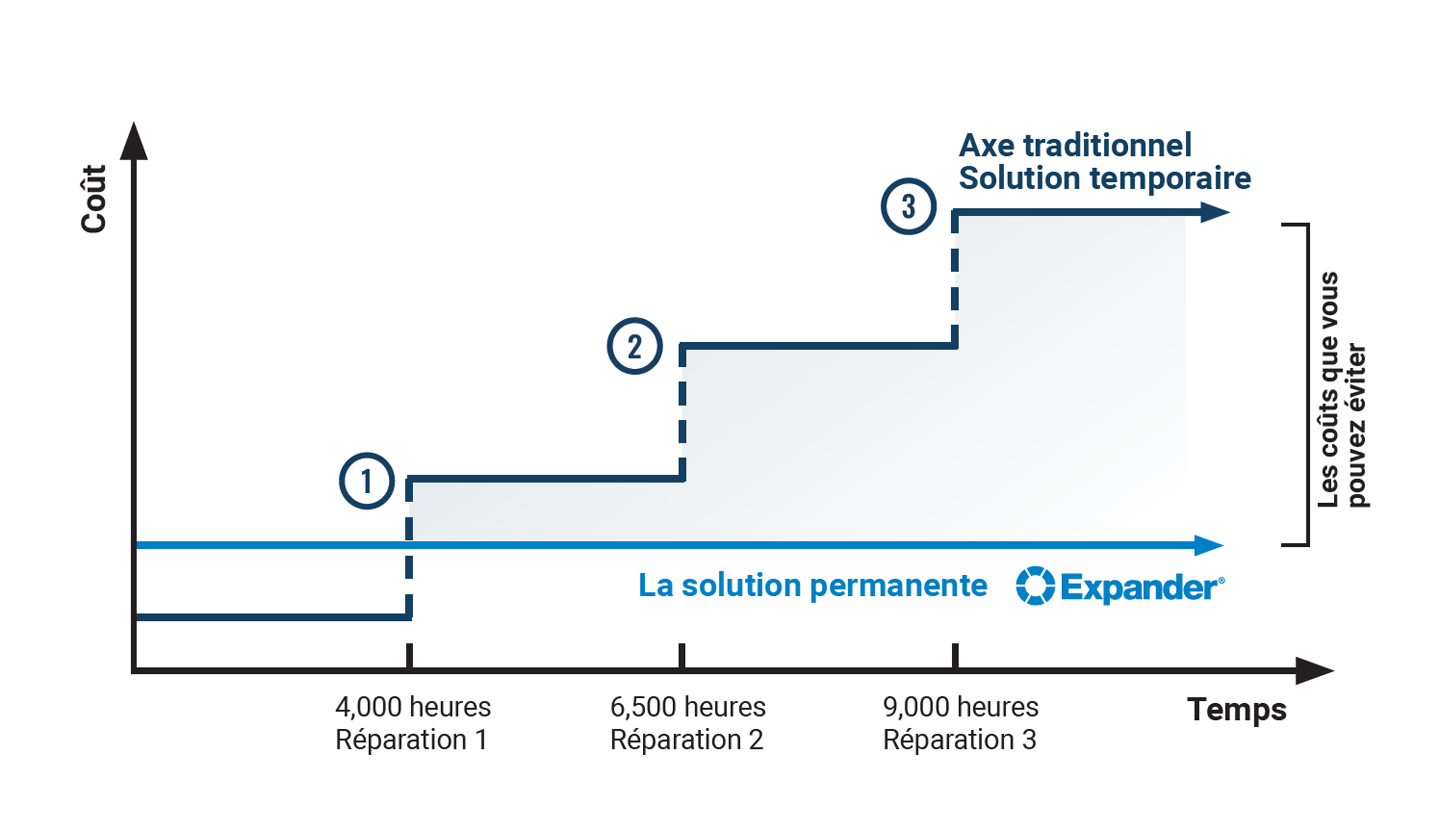

Savings Realized from the First Repair

Expander shafts are used in both original equipment manufacturing (OEM) and aftermarket applications as a repair solution during maintenance.

The Expander system starts saving you money as soon as it is installed.

The usual recurring maintenance costs associated with traditional shaft replacement are completely eliminated with the permanent Expander solution..

Advantages of Expander Products :

- Easy and Quick to Install and Dismantle (even in the field)

- Cost-Effective and Permanent Solution

- No Special Tools Required

NORD-LOCK GROUP: A Hub of Innovation and Engineering

Nord-Lock Group offers essential technologies to tackle your bolting challenges..

In 1982, the original Nord-Lock® wedge-locking technology was developed, providing a reliable solution for securing bolted assemblies.

Since then, our range of technologies and assembly expertise has become the most comprehensive on the market, integrating Superbolt® mechanical tensioners, Boltight® hydraulic tensioners, and Expander® shafts.

All solutions are developed and manufactured in-house, ensuring they meet the highest industry standards. Our dedicated team of experts works closely with clients worldwide.

EXPANDER® LIBRARY:

Discover our EXPANDER® media library: product catalog, presentation brochure, and company information.

Access essential resources with a single click to learn more about this brand.

Take advantage of comprehensive and up-to-date documentation to meet your professional needs.